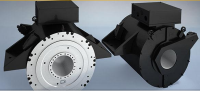

PCE-MWM 210 VHF band sensor / continuous moisture measurement in wood pellets, chips, sawdust and similar materials

(container / mixer)

Dich vụ sửa chữa, bảo dưỡng, cải tiến các hệ thống dây chuyền tự động công nghiệp

- For industrial continuous production of wood pellets, chips, sawdust and similar materials, in-line moisture measurement for monitoring and controlling the mixing process is important. Consistent quality of every batch, reduction of the consumption of wood, and shortest possible mixing times are the criteria which are important in wood product production. Sensors of PCE Instruments help meet those criteria through highly accurate moisture measurement.

- The production of wood products is subject to, e.g. large fluctuations caused by varying moisture contents of the raw and auxiliary materials (sands, aggregates). A reduction of these moisture fluctuations during storage is possible, but not easy to implement. Therefore, it makes more sense to do continuous online / inline moisture measurement during the mixing process to determine the respective component humidities or moisture. Subsequently, the dosage of water is controlled. This procedure not only allows the equalization of the quality of each batch but also reduces the mixing time.

- PCE Instruments planar sensors are at a suitable point in the ground or screwed in the wall of the mixer (e.g.pan mixer, screw mixer). It can also be used when other variants or types are used, e.g. for in-line moisture measurement of additives (hopper for sand).

- In combination with a control system (SCADA or DCS) or a real-time moisture measurement sensor control & control unit of PCE Instruments, this is a true control of a sensor for measuring humidity.

| Technical Data: | |

| Measuring Range | 0 ... 100 % |

| Maximum permissible error (absolute) | Δ= 0.035 +0.05·W |

| Operating temperature range | -20 ... +80 °C / -4 ... 176 °F |

| Working mode | continuous operation |

| Measuring interval | 1 s |

| Power supply | 24 (18 ... 36) VDC |

| Current consumption | 200 mA |

| Warm-up time (start-up) | 90 min |

| Outputs | RS 485 Modbus RTU, 4-20 mA [RS485: max. cable length 1000 m; 4-20 mA: max. cable length 100 m (max. cable length to SPS unit)] |

| Inputs | 2 x digital 24 VDC |

| Dimensions (sensor) | 164 х 120 mm / 6.4 x 4.7 in |

| Dimensionen (electronics unit) | 255 х 170 x 60 mm / 10 x 6.6 x 2.3 in |

| Protection (sensor) | IP67 |

| Protection (electronics unit) | IP54 |

| Weight (sensor) | 3.5 kg |

| An integrated temperature sensor continuously measures the temperature of wood pellets, chips, sawdust and similar materialsThe r eadings are displayed. These are used internally for temperature compensation). | |

| Please note that we will need further information to provide a final price for supply and fit. We will need to know what materials are to be measured, we will need samples of the material, and we will need a technical drawing showing where the sensor is to be installed. |

|