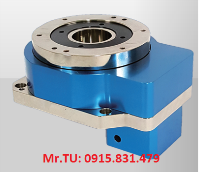

Double worm gear unit ZAE Vietnam

Hãng sản xuất: ZAE

Double worm gear unit ZAE Vietnam

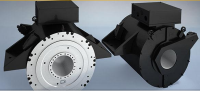

By combining two worm gear units to form a double worm gear unit, ratios of up to 6400:1 can be achieved. These double worm gear units use the same modular system as the single-stage gear units. This makes a large number of variants already possible with standard components.

Torques on the output side

T2;zul : 50 Nm bis 70000 Nm

Ratio(s) (*)

- 25:1 bis 6400:1

Sizes (centre distance)

- 50 bis 400

Use

These gear units are used, for example, in steelworks or for tracking on antenna systems.