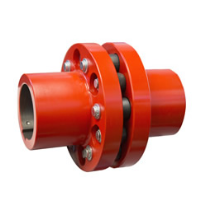

Shoe Brakes Vietnam

Hãng sản xuất: Westcar

Shoe Brakes Vietnam

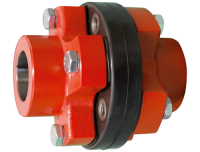

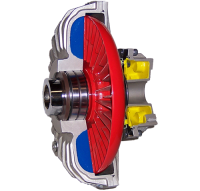

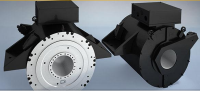

Service brakes, safety brakes, emergency brakes welded steel structure in accordance with standards DIN 15435

Applications

- Service brake

- Safety brake

- Emergency brake

Original Equipment

- Welded steel structure according to DIN 15435 - epoxy resin painting (2 coatings) - RAL 3000 final colouring.

- Manganese phosphated pins.

- Self-lubricating bushes on main joints.

- Light alloy drums with asbestos free bonded linings.

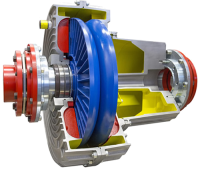

- Friction coefficient μ=0,42.

- Braking torque scale indicator.

Operation

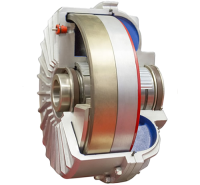

- The WESTCAR drum and disc brakes are negative type.

- The braking force is obtained by a spring, this one through a lever system, actuating the braking pad against the drum/disc

- An electrohydraulic or pneumatic thrustor is used to win the spring compression and opening the brake.

- The braking force of the linings against the drum can be modulated by adjusting the spring compression.

- Braking torque changes depending on the spring force modulation.

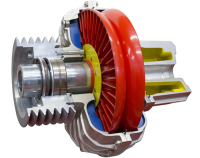

Optionals

- Automatic wear compensation (RG).

- Linings max wear indicator (fitted on rod) (FCU).

- Open brake indicator, either fitted on thrustor or on spring set (to be specified) (FCA).

- Larger drum (50% wider) (L).

- Stainless steel pins (INOX)